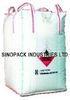

Tall Four-panel polypropylene woven Big Bag FIBC up to 4400lbs industrial use

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Tall Four-panel polypropylene woven Big Bag FIBC up to 4400lbs for

Tall Four-panel polypropylene woven Big Bag FIBC up to 4400lbs for industrial use

Specifications:

|

Shape |

U-panel / Four-panel bag |

|

Capacity |

Up to 4400LBS |

|

Safety factor |

5:1 |

|

Base size |

41*41’’ |

|

Height |

As per request |

|

Color |

White, Black, Orange, Blue |

|

Material |

100% virgin polypropylene, 5OZ to 7OZ |

| Top type |

skirt top, with filling spout: 14’’(D)*18’’, |

|

Bottom type |

discharge spout: 14’’(D)*18’’ with star petal or iris spout, with flap |

|

Lifting loops |

width: 2’’ 10’’ high side-seam loops |

| Anti-sift |

1. coated fabric + all seams double filler cords 2. uncoated fabric + PE liner |

|

Perimeter belt |

Width: 1.2’’, 2’’ |

|

UV stabilized |

1% UV to 3% treated |

|

Document pouch |

PE ziplock, Envelope type |

|

Label |

As per request |

|

Printing |

Four colors at most in one side |

|

Stitching |

Plain stitching, chain stitching, overlock stitching |

|

Packing |

Packed on pallets, 20pallets/20'FCL, 44pallets/40'FCL |

|

Lead time |

25days for 1 x 20'FCL; 45days for 1 x 40'FCL |

Description:

1. The popular Four-Panel bulk bag is our original polypropylene design and has become the industry standard by which others are judged. The versatile, cost-effective four-panel construction is excellent

for a variety of applications and is available custom designed or from our in-stock selection. The U-Panel variation consists of two side panels attached to a ‘u-shaped’ single piece ‘side-bottom-side’ unit.

2. The capacity of this type:

Volume: Two to 120 cubic feet.

Up to: 4,400 lbs.

3. The four-panel and u-panel construction has unique hems on all side panels, reducing strength loss and sifting from sewing lines. Fabric edges are turned to the outside to reduce potential contamination.

Application:

FIBC Bags with advantages of light weight, moisture-proof, dust-proof, no leakage, resistance to radiation, Acid corrosion, strong security, excellent performance, able to carry chemical, cement, grains, minerals and other kinds of powder, granular, quick-like material, applicable to mechanical loading, is the ideal products to reduce costs of packaging and transport.

- Type A: No special electrostatic safety features and are just common-used bags.

- Type B: Being not capable of generating propagating brush discharges. The wall of this FIBC exhibits a breakdown voltage of 4 kilovolt or less.

- Type C: Conductive FIBC. Constructed from electrically conductive fabric, designed to control electrostatic charges by grounding. A standard fabric contains conductive threads or tape.

- Type D: Anti-static FIBCs essentially refer to those bags which have anti-static or static dissipative properties without the requirement of grounding.

PRODUCTION PROCESS & PALLET PACKING & INSTRUCTION:

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

SINOPACK INDUSTRIES LTD [China (Mainland)]

Business Type:Manufacturer

City: Nanjing

Province/State: Jiangsu

Country/Region: China (Mainland)